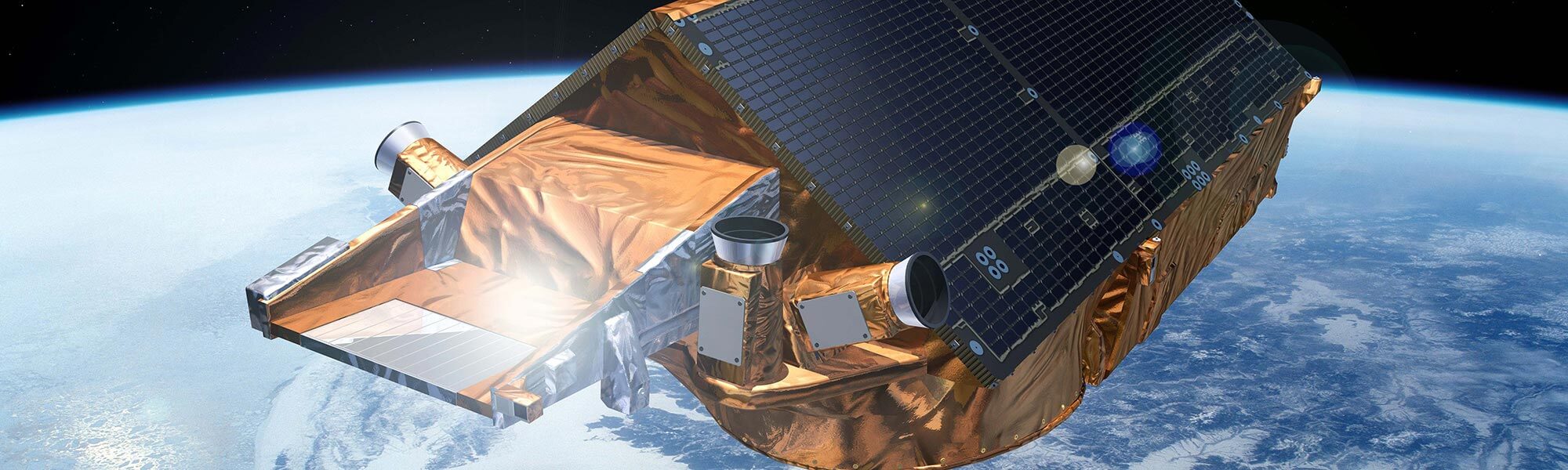

Demisable Propellant Tank technologies (DUST)

Between 2019 and 2025, ISP worked closely with Haydale plc under UKSA ARTES funding to:

- Identify materials and processes already in, or suitable for, the spaceflight marketplace that could be readily harnessed to produce a new range of gas or liquid propellant tanks, without ..

- any loss of technical performance or in-orbit reliability;

- the material wastage and lead times associated with metallic liner/shell;

- the complexity of non-UK/European supply chain or development network;

- the costs and production delays introduced by using heritage processes.

- Initiate a network of non-space commercial entities to perform reliable low-cost processes from parallel sectors to maintain low recurring costs of the flight tanks;

- Perform validation tests of the selected material condition in a Plasma Wind Tunnel to demonstrate demiseability attributes and establish a thermal demise model;

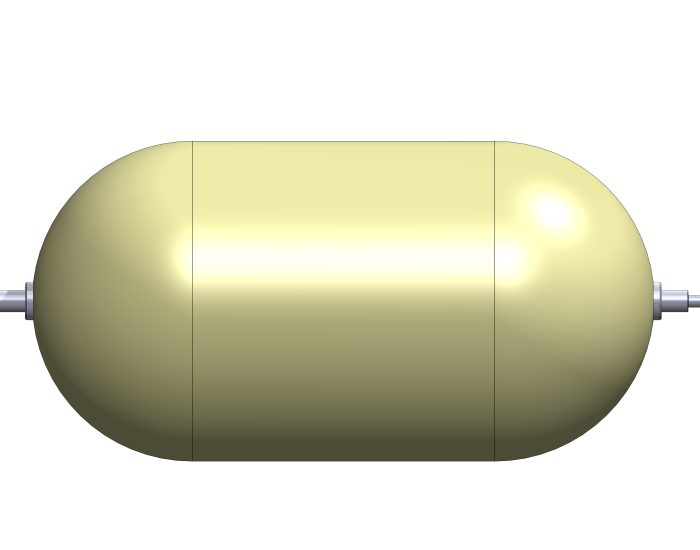

- Prove the ability of the design approach to scale up or down equally to meet volume requirements, between 10 litres and 180 litres;

- Produce Pathfinder test articles to demonstrate the viability of the selected material and process approach and enable lessons to be learned through production trial and error, until the optimum solution was arrived at;

- Produce Engineering Model test articles to demonstrate the full range of performance capability (pressure, thermal and mechanical loads), correlate the safety design margins and validate the Finite Element Models.

- The successful conclusion will enable system manufacturers to source custom-design propellant tanks at <50% (tbd) of current market price, and delivery against specific requirements in weeks, rather than months or years.